PCE liquid, or polycarboxylate superplasticizer liquid, is a third-generation, high-performance water reducer that holds a key position in the concrete industry. Its molecular structure features a distinct comb-like structure, composed of a main-chain anchoring group and pendant hydrophilic groups. The main-chain anchoring groups act as “grips,” tightly adsorbing onto the surface of cement particles; the pendant hydrophilic groups extend into the aqueous solution, providing the structural foundation for the superplasticizer to function effectively. This unique molecular structure transcends the performance limitations of traditional concrete water reducing admixtures and opens a new chapter in the field of concrete admixtures.

This product is inherently non-toxic and non-polluting, making it a green chemical building material. During production and use, it releases no harmful substances into the environment, aligning with the current construction industry’s pursuit of green and sustainable development, and providing an ideal admixture for eco-friendly construction.

Performance Advantages of PCE Liquid

- Ultra-High water reduction rate. Compared to traditional high-efficiency water reducers such as naphthalene-based ones, PCE liquid offers significant water reduction advantages, with increases of up to 35%-45%. In actual concrete preparation, this can significantly reduce mixing water usage. For example, when preparing C50 strength grade concrete, using polycarboxylate superplasticizer liquid can reduce the water-binder ratio from the conventional 0.4 to approximately 0.32, significantly optimizing the concrete’s internal structure and providing strong support for the production of high-strength, high-performance concrete.

- Excellent slump retention. Ready-mixed concrete exhibits a slump loss of less than 15% within two hours. This characteristic is crucial for commercial concrete that requires long-distance transportation or long waiting times for construction. For example, in large-scale urban construction projects, where concrete mixing plants are located far from the construction site, the use of PCE liquid high-efficiency water reducer ensures that concrete maintains excellent fluidity during transportation and meets pumping and other construction process requirements upon arrival. This ensures smooth construction progress, avoids excessive slump loss that could render concrete unusable, and reduces the risk of material waste and construction delays.

- Excellent adaptability. It exhibits stable water-reducing and performance-adjusting effects on various cement types, such as ordinary Portland cement, slag Portland cement, and fly ash Portland cement. In actual projects, cement sources vary depending on project location. The wide adaptability of PCE liquid eliminates the need for frequent formulation adjustments for different cement types, significantly improving construction convenience and efficiency.

- Low shrinkage. The polycarboxylate superplasticizer liquid effectively reduces shrinkage and deformation of concrete during the hardening process, reducing shrinkage by 30%-40% compared to concrete without the water reducer. This characteristic is crucial for large-scale concrete projects, such as bridge foundations and dams. It significantly reduces cracks caused by shrinkage, enhances the integrity and durability of concrete structures, and extends the service life of the project.

| Items | Standard | ||||

| PCE Liquid (High Water Reduction) | PCE Liquid (High Slump Retention) | PCE Powder | |||

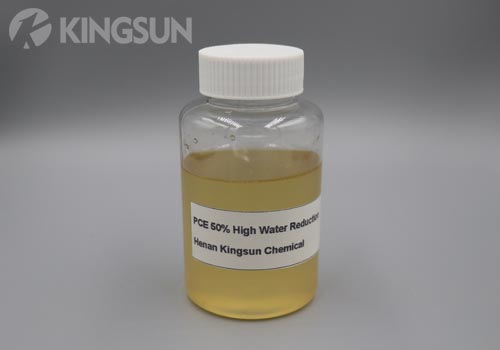

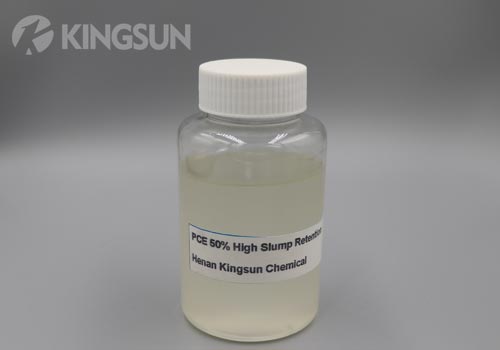

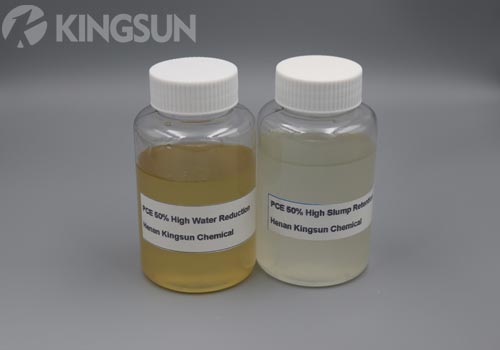

| Appearance | Light Yellow Liquid | Clear Transparent Liquid | White Powder | ||

| Solid Content, % | 50±1.0 | 50±1.0 | 98±1.0 | ||

| Density (23℃) (kg/m3) | 1.13±0.02 | 1.05-1.10 | 600±50 | ||

| PH | 6.5-8.5 | 6.5-8.5 | 9.0±1.0 | ||

| Chloride Content,% ≤ | 0.1 | 0.1 | 0.1 | ||

| Na2SO4 (by solid content), % ≤ | 4.0 | 4.0 | 4.0 | ||

| Solubility | Completely Soluble | ||||

| Water reducing ratio, % ≥ | 25 | ||||

| Packing | The packing of PCE liquid is 230kg PE drum, 1100kg IBC tank or flexitank. But for PCE superplasticizer powder, its packing is 25 kg PP woven bag. | ||||

-

Applicable Scenarios

-

Mechanism of Action

- High-rise building construction. High-rise building construction places extremely high demands on concrete strength and pumpability. PCE liquid helps formulate highly fluid, high-strength concrete to meet the pumping requirements of high-rise construction, ensuring smooth concrete delivery to the designated height and location while also ensuring that the concrete structural strength meets design requirements, safeguarding the building structure’s safety.

- Large-scale bridge construction. Bridge construction involves pouring large volumes of concrete, placing stringent demands on concrete durability and crack resistance. PCE liquid high-efficiency water-reducing agent’s low shrinkage and high durability effectively reduce the risk of cracking during concrete pouring and use, improving the impermeability and erosion resistance of bridge structures and extending their service life.

- Hydraulic structure engineering. Hydraulic structures such as dams and ports are exposed to humid or even underwater environments for extended periods, placing extremely high demands on concrete’s impermeability and frost resistance. Polycarboxylate superplasticizer liquid optimizes the internal pore structure of concrete, increases its density, and significantly enhances its impermeability and frost resistance, resisting the penetration of water and corrosive media, ensuring the long-term stable operation of hydraulic structures.

- 3D printing concrete. 3D printing concrete requires “creamy-smooth” fluidity to pass smoothly through the printing nozzle. PCE polycarboxylate ether liquid can reduce the water-binder ratio to approximately 0.28, imparting excellent fluidity and extrudability to the concrete while ensuring rapid setting after extrusion. This meets the special material property requirements of 3D printing concrete and promotes the development and application of 3D printing technology in construction.

- Electrostatic repulsion. When the main chain anchoring groups in the PCE superplasticizer molecules adsorb onto the surface of cement particles, they impart a like charge to the cement particles. Based on the principle that like charges repel each other, electrostatic repulsion is generated between the cement particles, allowing them to disperse and release trapped water, thereby reducing water content.

- Steric hindrance. The side chain hydrophilic groups extend in aqueous solution, forming a thick solvation layer. These solvation layers act as “cushions,” creating steric hindrance when cement particles approach each other, preventing them from reaggregating and maintaining their dispersion, further enhancing the concrete’s fluidity and slump retention.

- Improved surface wettability of cement particles. Superplasticizer molecules adsorbed on the surface of cement particles reduce the interfacial tension between the cement particles and water, making it easier for water to wet the cement particles. This improves the uniformity of the cement particle dispersion, promotes a more complete cement hydration reaction, and enhances the strength and durability of concrete.

Precautions for Use

- Dosage Control. Strictly follow the product instructions and the optimal dosage determined by testing. A dosage that is too low will not fully achieve its water-reducing and workability-adjusting effects; a dosage that is too high may cause concrete segregation and bleeding, impacting concrete quality. Generally, the dosage of PCE liquid is 0.5% to 1.5% by weight of cement. The specific value should be determined through testing based on project conditions.

- Compatibility with Other Admixtures. Do not use with naphthalene-based or melamine-based water reducers. Use with sulfamate-based water reducers, as flocculants may form and should be used with caution. If used with other admixtures, compatibility testing must be conducted to ensure synergy and no adverse reactions occur.

- Storage Conditions. Store in a cool, dry, well-ventilated warehouse, away from direct sunlight and high temperatures. The storage temperature should be controlled between 5 and 35°C to prevent performance degradation due to excessively high or low temperatures. The product shelf life is usually 6-12 months. After the shelf life, the performance needs to be retested and it can only be used after passing the test.