PCE concrete admixture is a kind of high-efficiency water reducer that can be mainly used for concrete. Adding the amount of pce admixture into concrete, the slump and expansion loss of the concrete are small, the fluidity is large, and the water retention, cohesiveness, and climate adaptability all perform well. PCE superplasticizer belongs to polymer surfactants, so it can also be used in other paste-like materials, such as gypsum and ceramics, to reduce water content. PCE based admixture generally has a water reduction of more than 25% in concrete and has good compatibility with the base material.

Kingsun PCE Powder

Kingsun PCE Powder PCE Liquid

PCE Liquid PCE Chemicals

PCE Chemicals Polycarboxylate Superplasticizer Manufacturer

Polycarboxylate Superplasticizer Manufacturer Polycarboxylate Superplasticizer Powder

Polycarboxylate Superplasticizer Powder Polycarboxylate Superplasticizer Supplier

Polycarboxylate Superplasticizer Supplier Polycarboxylate Ether Liquid

Polycarboxylate Ether Liquid

PCE based superplasticizer is an important component in high-performance concrete. In addition to having a high water reduction effect, it can also effectively control the slump loss of concrete, which can largely meet the requirements of concrete durability. At the same time, PCE based admixture also has many outstanding characteristics such as low dosage, good adaptability to admixtures, little impact on dry shrinkage of concrete, no formaldehyde, and environmental protection.

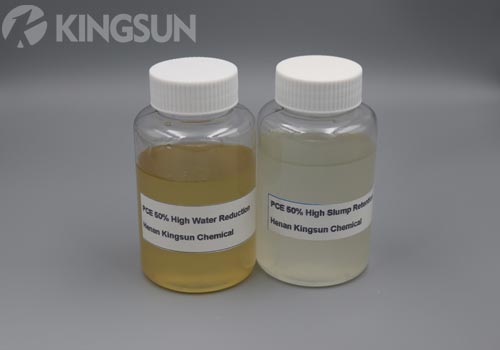

There are three types of PCE concrete admixtures for sale in Kingsun. They are PCE Powder, PCE Liquid (High Water Reduction), PCE Liquid (High Slump Retention). But their appearance and functions are different. You can choose the right PCE concrete admixture according to your needs. Please check the specifications in the table below:

| Items | Standard | ||||

| PCE (High Water Reduction) | PCE (High Slump Retention) | PCE Powder | |||

| Appearance | Light Yellow Liquid | Clear Transparent Liquid | White Powder | ||

| Solid Content, % | 50±1.0 | 50±1.0 | 98±1.0 | ||

| Density (23℃) (kg/m3) | 1.13±0.02 | 1.05-1.10 | 600±50 | ||

| PH | 6.5-8.5 | 6.5-8.5 | 9.0±1.0 | ||

| Chloride Content,% ≤ | 0.1 | 0.1 | 0.1 | ||

| Na2SO4 (by solid content), % ≤ | 4.0 | 4.0 | 4.0 | ||

| Solubility | Completely Soluble | ||||

| Water reducing ratio, % ≥ | 25 | ||||

| Packing | The packing of PCE liquid is 230kg PE drum, 1100kg IBC tank, or flexitank. For PCE Powder, its packing is 25 kg PP woven bags. | ||||

- Benefits of PCE Concrete Admixture

- Performance of PCE

- Uses of PCE Admixture

Economic benefits. Due to the use of pce admixture in concrete, the water-to-cement ratio of the concrete is greatly reduced, which provides good conditions for adding a large number of various mineral admixtures in the concrete. The use of a large number of mineral admixtures improves the durability of the concrete, reduces the heat of hydration of the concrete, and enables various performance indicators of the concrete to meet relevant technical requirements. At the same time, the dosage of cement has been greatly reduced, the cost of concrete production has been reduced, and considerable economic benefits have been achieved.

Social benefits. The production process of pce concrete admixture for sale is environmentally friendly and does not produce any waste gas or waste. Through the use of pce admixture and mineral powder and fly ash, the consumption of non-renewable resources is reduced, and the carbon dioxide emissions are reduced. On the other hand, it consumes a large amount of industrial waste such as fly ash and slag powder, zeolite powder, steel slag powder, etc., which reduces environmental pollution, meets the national energy conservation, environmental protection, waste disposal requirements, and achieves significant social benefits.

- PCE water reducing agent has the characteristics of low dosing and high water reduction. The water-saving rate is 25% to 40%, which is suitable for the preparation of high-strength and high-performance concrete.

- Adding polycarboxylate pce admixture in concrete, the concrete slump loss over time is small. Conducive to long-distance transportation.

- It has obvious hardening and reinforcing effects on concrete. 3d strength can be increased by 50 ~ 100%, 7d, 28d strength can be increased by 30-50%, and the strength in the later period has maintained a steady increase.

- The fresh concrete has good processability, good pumpability, and no segregation.

- No chlorine, low alkali, no corrosion to steel bars or aggregates.

- The concrete air content can be adjusted according to the needs of the project.

- Significantly improve the frost resistance, impermeability, low carbon capacity, and shrinkage resistance of concrete. It can significantly extend the life of the concrete.

- PCE based admixture has good adaptability and can meet a variety of cement varieties. It is especially suitable for high-strength, high-flow, high-performance concrete formulated with active admixtures such as fly ash and slag.

- PCE concrete admixture is non-toxic, non-polluting during production, and safe to health and the environment. Meets current environmental standards for internal and external buildings.

- The dosage of PCE admixture is 0.1%-1.5% of the total weight of the gelling material, and the usual dosage is 0.8%-2.5%. Before use, a trial mix test of concrete should be carried out to find the best dosage.

- PCE concrete admixture cannot be mixed with naphthalene sulfonate formaldehyde. The mixers and mixer trucks that had been used for poly naphthalene sulfonate must be cleaned before using pce chemical, otherwise, the water-reducing effect may be lost.

- When the PCE admixture is used, it can be directly used in pce liquid form, or it can be formulated into a solution with a certain concentration for use.

- Because the water reduction rate of concrete mixed with PCE superplasticizer is relatively large, the slump is highly sensitive to water consumption, and the water consumption must be strictly controlled during use.

- Polycarboxylate ether superplasticizers have good adaptability to most types of cement, but for individual types of cement, the water reduction rate may be low and the slump loss may be large. In addition, the fineness and storage time of the cement may affect the use effect of the polycarboxylic acid superplasticizer. At this time, it is recommended to increase the dosage or compound other retarding components to solve the problem.

- After mixing with PCE admixture, the air content of concrete increases (generally 2%-5%), which is beneficial to improve the workability and durability of concrete.

- Due to the small content of PCE based admixture and high water reduction rate, the use of this product to configure various types of high-performance concrete above C45 can greatly reduce project costs and has significant technical and economic benefits; it is used to prepare C45 or less Although the cost of grade concrete is relatively high, the overall cost of concrete can be reduced by increasing the dosage of mineral admixtures, which also has certain technical and economic benefits.

Kingsun - The Leading PCE Concrete Admixture Manufacturer

- As a leading manufacturer of PCE concrete admixture, Kingsun company has more than 15 years’ experience in construction chemicals industry.

- Kingsun has its own factory, advanced production lines, large warehouse, R&D center and professional sales team.

- All of Kingsun products have passed many certifications, such as ISO 9001, ISO 4001, SGS, etc.

- We always supply high quality products, competitive PCE admixture prices and good services for all the customers.

- At present, our products have been exported to more than 30+ countries, including Turkey, Mexico, Bahrain, Peru, Qatar, Brazil, Indonesia, Thailand, Philippines, Singapore, Malaysia, Israel, Pakistan, Bangladesh, United Arab Emirates, Saudi Arabia, Jordan, Nigeria, Ukraine, Russia, India, South Korea, Egypt, Tanzania, etc.